All Categories

- Industrial LCD display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA Module

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO Module

- INTEL

- Key board

- FAIRCHILD

- Motherboard

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- OMRON

- Relay

- Controller

- Photoelectric Switch

- Photoelectric Sensor

- Original

- Fan

- Motor Driver

- Limit Switch

- Amplifier

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformer

- Fiber Optic Sensor

- Protection Relay

- Temperature Controller

- Proximity Switch

- Switch Sensor

- Siemens

- Industrial board

- HMI Touch Glass

-

HMI Full Machine Whole unit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley automation HMI Touch Panel

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- other

- Module

- lcd inverter

- Membrane Keypad Switch

- Winni Touch Screens

- Frequency Inverter

- Servo Motor

- PLC

Recommended Products

Home » News

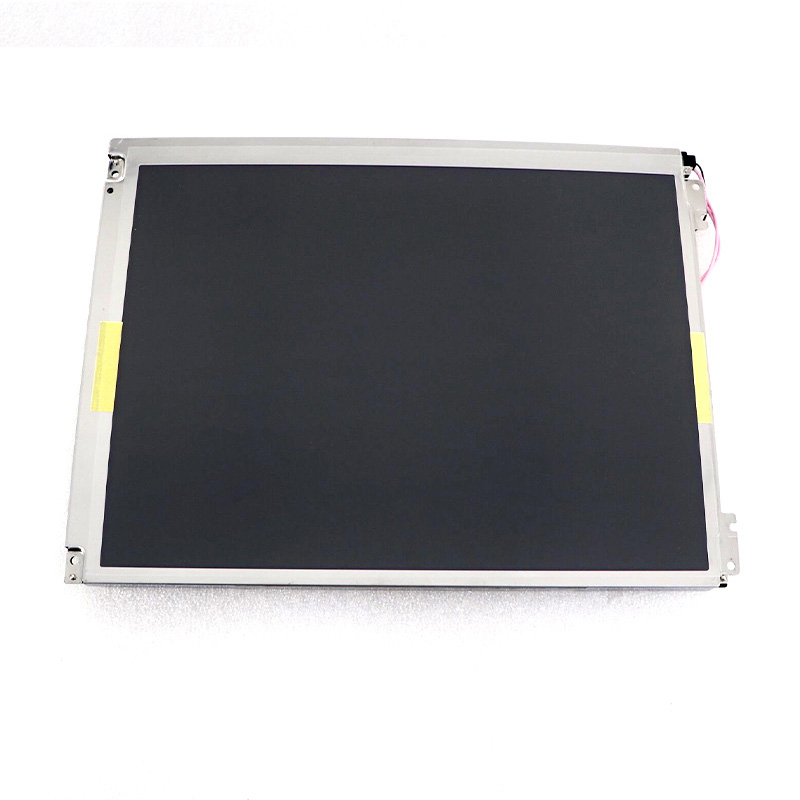

AA121SK22 Mitsubishi LCD Panel Display

In the intricate world of industrial automation and high-performance display systems, the Mitsubishi AA121SK22 LCD panel stands as a critical component, often operating behind the scenes to deliver the visual clarity and reliability demanded by mission-critical applications. This is not a consumer-grade monitor but a specialized industrial panel module, the core engine that powers sophisticated human-machine interfaces (HMIs), medical imaging displays, and advanced control room consoles. Understanding its specifications, capabilities, and integration nuances is essential for engineers, system integrators, and procurement specialists.

This article delves deep into the AA121SK22, moving beyond basic datasheet parameters to explore its technological significance, application landscapes, and practical considerations for deployment. We will dissect its core features, analyze the environments it is built for, and provide a comprehensive guide for sourcing, integrating, and maintaining this pivotal piece of industrial hardware, offering valuable insights for professionals who rely on precision and durability in their display solutions.

Decoding the AA121SK22: Core Specifications and Technology

At its heart, the Mitsubishi AA121SK22 is a 12.1-inch diagonal TFT LCD panel module with a native resolution of 800 x 600 pixels (SVGA). This aspect ratio and resolution remain staples in industrial contexts due to their compatibility with legacy systems and specific software interfaces. The module typically employs a high-performance CCFL (Cold Cathode Fluorescent Lamp) backlighting system, known for its uniform brightness and stable performance over a wide temperature range, a crucial factor for industrial settings.

Key technological features include its wide viewing angles, essential for panels viewed from off-axis positions in control rooms or medical carts, and its robust color reproduction. The interface is typically LVDS (Low-Voltage Differential Signaling), the standard for reliable, low-noise data transmission in demanding environments. Understanding these core specs—the active area dimensions, pixel pitch, luminance, and power requirements—forms the foundational knowledge for evaluating its suitability for any given project, distinguishing it from commercial alternatives built for shorter lifecycles and less rigorous conditions.

The Industrial Application Ecosystem

The true value of the AA121SK22 is realized in its application ecosystem. It is engineered for environments where failure is not an option. In industrial automation, it serves as the primary visual interface for PLC (Programmable Logic Controller) systems, CNC machine controls, and robotic workcell supervision, where it must resist vibration, electrical noise, and continuous operation.

In the medical field, this panel can be found in diagnostic equipment, patient monitoring systems, and surgical displays, where grayscale precision and absolute reliability are paramount. Furthermore, it is utilized in transportation (avionics test equipment, marine navigation), kiosks, and specialized military hardware. Its design prioritizes long-term availability and consistent performance, aligning with the extended product lifecycles of the machinery it becomes a part of, often far exceeding the typical 3-5 year lifecycle of consumer electronics.

Integration Challenges and Interface Considerations

Integrating a raw panel like the AA121SK22 is not as simple as plugging in a standard monitor. It is a module requiring a supporting ecosystem. The primary challenge lies in the interface and controller board. The LVDS signals from the panel must be processed by a compatible LCD controller board that translates video input signals (e.g., VGA, DVI, HDMI) into the precise LVDS format the panel understands.

Engineers must also design or source a suitable power supply for both the panel logic and the CCFL backlight inverter, ensuring stable voltage and protection against surges. Mechanical integration involves careful mounting to manage heat dissipation and prevent stress on the panel. Furthermore, considerations around the backlight lifetime (often rated in tens of thousands of hours) and its eventual replacement are part of the long-term design calculus, influencing the total cost of ownership.

Sourcing and Supply Chain Dynamics

Given its industrial nature, sourcing the AA121SK22 involves navigating a specialized supply chain. Mitsubishi Electric may have ended direct production or shifted focus, making the module part of the industrial electronic components aftermarket. Reliable suppliers are often specialized distributors or brokers who deal in legacy and hard-to-find components.

Procurement professionals must be vigilant about authenticity and condition. New old stock (NOS), refurbished, or pulled-from-working-systems units are common. Verifying source credibility, obtaining genuine datasheets, and ensuring compatibility with specific lot codes or revisions (like the AA121SK22-TT01) is critical. This landscape underscores the importance of building relationships with trusted suppliers and planning for component lifecycle management early in the system design phase.

Performance Optimization and Calibration

To extract maximum performance, the AA121SK22 often requires calibration and optimization, especially in color-critical or grayscale-diagnostic applications. This involves adjusting the controller board's settings to fine-tune gamma curves, color temperature (e.g., to the DICOM standard for medical grayscale), and uniformity.

Brightness stabilization circuits may be necessary to compensate for CCFL aging. Environmental factors like ambient light in a factory or control room must also be considered, potentially necessitating the use of optical bonding or high-brightness versions to reduce glare. This level of tuning transforms the panel from a generic component into a tailored solution that meets the exact visual ergonomic and diagnostic needs of the end-user, enhancing both performance and user safety.

Future-Proofing and Legacy System Support

As technology advances, the AA121SK22 represents a bridge between legacy industrial systems and modern needs. A key strategy is future-proofing through intelligent inventory management for long-term maintenance contracts or designing new systems with upgrade paths. Some integrators explore LED backlight retrofit kits to replace aging CCFL systems, offering improved efficiency, longevity, and reduced heat.

The discussion also involves evaluating when a direct panel replacement remains the most cost-effective and reliable strategy versus a full system upgrade to a newer display technology. The decision hinges on factors like software compatibility, certification requirements (e.g., medical or aviation), and the monumental cost of re-engineering entire deployed systems. The AA121SK22's enduring relevance is a testament to its robust design and the conservative, reliability-first nature of the industries it serves.

FAQs: Mitsubishi AA121SK22 LCD Panel

1. What is the AA121SK22?A 12.1" SVGA industrial TFT LCD panel module by Mitsubishi, commonly used in HMIs and medical equipment.

2. What is its resolution and aspect ratio?800 x 600 pixels (SVGA) with a 4:3 aspect ratio.

3. What type of backlight does it use?It typically uses a CCFL (Cold Cathode Fluorescent Lamp) backlight system.

4. What is the main interface?It uses an LVDS (Low-Voltage Differential Signaling) interface.

5. Can I use it as a standalone monitor?No, it requires an external LCD controller board to process video input signals.

6. Where is it commonly used?In industrial automation, medical devices, transportation systems, and kiosks.

7. Is it still in production by Mitsubishi?It is likely a legacy part, sourced through specialized industrial component distributors.

8. What does "SK22" in the part number indicate?It's a specific model/revision code; variations like AA121SK22-TT01 may exist with minor differences.

9. How do I replace the backlight?CCFL replacement requires careful disassembly; LED retrofit kits are sometimes available as an upgrade.

10. What are key sourcing considerations?Focus on supplier reliability, component authenticity (new old stock vs. refurbished), and exact revision matching.

Conclusion

The Mitsubishi AA121SK22 LCD panel is far more than a simple display; it is a precision industrial component engineered for reliability, longevity, and performance in demanding environments. Its significance lies not in cutting-edge consumer specs, but in its proven stability within the complex ecosystems of factory automation, medical diagnostics, and critical infrastructure.

Successfully leveraging this technology requires a deep understanding of its integration parameters, a strategic approach to sourcing within the specialized industrial aftermarket, and a commitment to calibration for optimal performance. For engineers and integrators, mastering the details of components like the AA121SK22 is essential for building systems that are not only functional but truly robust and sustainable over the long term, ensuring that vital visual interfaces continue to operate with unwavering clarity and dependability.