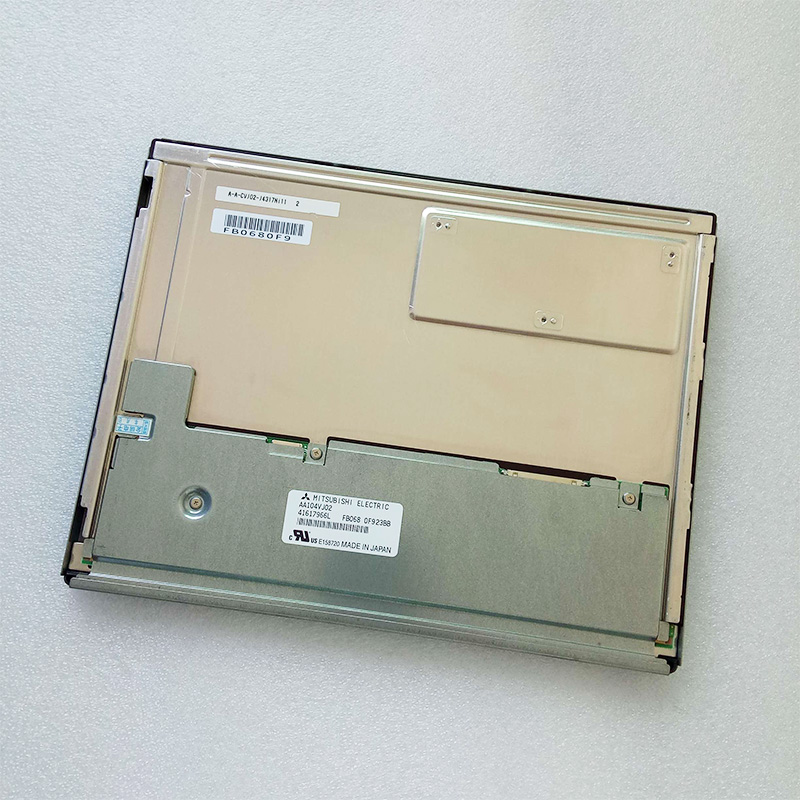

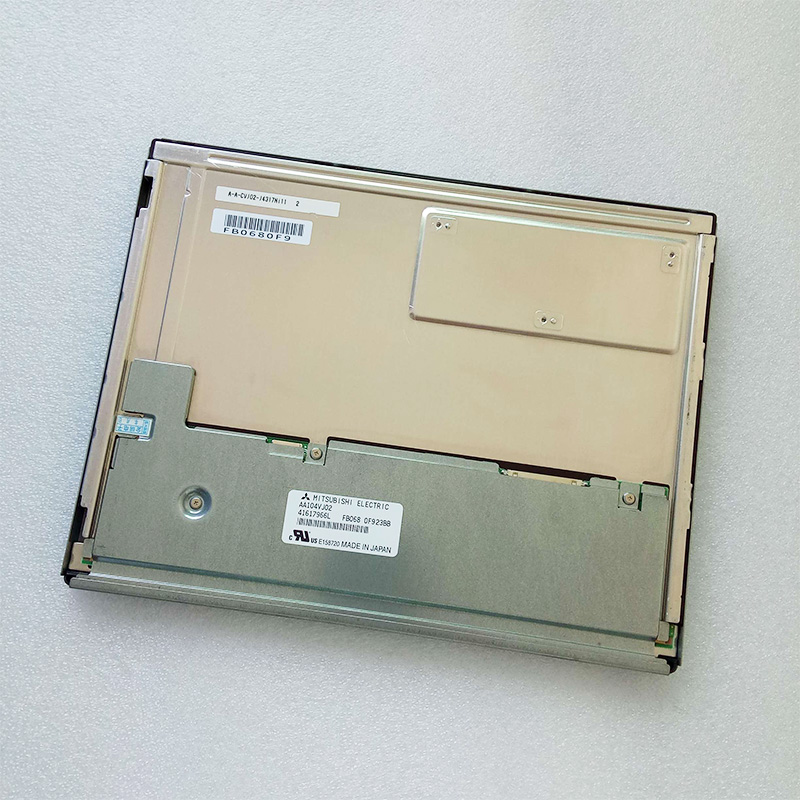

AA104VJ02 Mitsubishi 10.4 inch 640*480 Lcd Panel Display

In the intricate world of industrial and embedded systems, the display panel is far more than a simple window for information; it is the critical interface between complex machinery and human operators. Among the myriad of specialized components, the Mitsubishi AA104VJ02 stands out as a notable solution. This 10.4-inch LCD panel, with its 640 x 480 VGA resolution, represents a specific class of display engineered not for consumer entertainment, but for reliability, longevity, and performance in demanding environments.

This article delves into a comprehensive analysis of the AA104VJ02. We will move beyond basic specifications to explore its core technological architecture, the rationale behind its seemingly "low-res" design, and its precise application landscape. Understanding this panel requires a shift in perspective—from judging pixels to evaluating durability, signal compatibility, and integration challenges. Whether you are an engineer sourcing a replacement, a designer planning a new system, or a technical procurement specialist, this deep dive aims to provide the nuanced understanding necessary to evaluate where the Mitsubishi AA104VJ02 excels and where it fits within the broader ecosystem of industrial display solutions. Deconstructing the AA104VJ02: Core Specifications and Architecture

The Mitsubishi AA104VJ02 is built around a 10.4-inch diagonal amorphous silicon Thin-Film Transistor (a-Si TFT) LCD. Its native resolution of 640 x 480 pixels, known as VGA, is a defining characteristic. This panel utilizes a standard CCFL (Cold Cathode Fluorescent Lamp) backlighting system, which was the industry standard before the widespread adoption of LEDs. The interface is a critical 20-pin single-channel LVDS (Low-Voltage Differential Signaling), a robust and noise-resistant standard for transmitting high-speed video data in industrial settings. Understanding these specs in unison is key. The VGA resolution points to legacy system compatibility. The CCFL backlight, while consuming more power and having a finite lifespan compared to LED, provides a uniform and bright illumination that was preferred in many early 2000s designs. The LVDS interface underscores its purpose for integration into larger systems, requiring a compatible controller board. These are not arbitrary choices but a coherent architectural package designed for a specific era and type of application.

The Strategic Rationale Behind VGA Resolution in Modern Contexts

In an age of 4K and 8K displays, a 640x480 resolution may appear anachronistic. However, in industrial and embedded contexts, this "low" resolution carries significant strategic advantages. Firstly, it offers perfect compatibility with a vast installed base of legacy machinery, control systems, and test equipment whose graphics controllers output a native VGA signal. Upgrading the display often necessitates upgrading the entire control system, which is prohibitively expensive and disruptive.

Secondly, VGA resolution provides exceptional pixel density and clarity on a 10.4-inch screen. Text, numerical readouts, and schematic lines appear sharp and legible without the scaling issues associated with high-resolution panels on legacy software. Finally, the lower pixel count reduces the processing load on older CPUs and GPUs, ensuring smooth, real-time rendering of critical data without lag—a non-negotiable requirement in process control and monitoring.

Primary Application Ecosystems and Use Cases

The AA104VJ02 finds its home in environments where reliability trumps flashy specs. Its primary application ecosystems are characterized by long lifecycles and harsh operating conditions. Key use cases include: Industrial Human-Machine Interfaces (HMIs): Integrated into factory automation systems, PLC control stations, and manufacturing equipment.

Medical Diagnostic Equipment: Used in ultrasound machines, patient monitors, and diagnostic devices from the late 1990s and early 2000s.

Test and Measurement Instruments: Serving as the display for oscilloscopes, spectrum analyzers, and network analyzers.

Point-of-Sale (POS) and Kiosk Systems: Particularly in ruggedized or older models requiring long-term serviceability.

In these fields, the display is a component within a larger, costly system. The priority is maintaining operational continuity, making the AA104VJ02 a vital spare part for maintenance, repair, and overhaul (MRO) operations.

Integration Challenges and Interface Considerations

Integrating a panel like the AA104VJ02 is rarely a plug-and-play affair. The most prominent challenge is the CCFL backlight inverter. This panel requires an external high-voltage AC power source to drive the CCFL tubes, necessitating a compatible inverter board. This adds complexity, space requirements, and a potential point of failure compared to modern LED panels which use low-voltage DC. Secondly, the 20-pin LVDS interface must be matched with a controller board that supports the exact pinout, voltage, and timing parameters (often defined in a datasheet). Using an incompatible controller can result in no image, flickering, or damage. For engineers, successful integration involves sourcing or designing a controller that translates an incoming video signal (e.g., from a PC) into the precise LVDS format the panel expects, while also managing power sequencing and backlight control.

The LED Backlight Modification: A Viability Analysis

A common consideration for the AA104VJ02 is retrofitting it with an LED backlight to replace the aging CCFL system. This modification aims to reduce power consumption, eliminate the inverter, increase lifespan, and improve brightness uniformity. Technically, it involves carefully removing the CCFL tubes and installing an LED light bar with a diffuser, along with a simple DC-driven LED driver board. While viable, this is a delicate procedure. It requires disassembling the panel laminate in a clean environment to avoid dust ingress, which can ruin the display. The optical characteristics of the LED light bar and diffuser must closely match the original to prevent hotspots or dim edges. For high-value equipment, this modification can extend service life significantly. However, for most users, sourcing a direct CCFL replacement or a newer LED-native panel is often a more practical and less risky solution.

Market Position: Sourcing, Alternatives, and Legacy Support

The AA104VJ02 exists today primarily in the aftermarket and specialist component distribution channels. It is a discontinued panel originally manufactured by Mitsubishi Electric, but its long-term demand for MRO has sustained its availability through third-party suppliers and refurbishers. When sourcing, verifying authenticity and testing for dead pixels and backlight health is crucial. For those designing new systems, modern alternatives with LED backlights, wider viewing angles, and higher resolutions (like XGA 1024x768) are readily available. However, for legacy system support, the AA104VJ02 remains irreplaceable. Its market position is a testament to the decades-long lifecycles of industrial equipment and the critical need for compatible components to avoid costly system-wide upgrades, ensuring that this specific 10.4-inch VGA panel will remain relevant for years to come.

FAQs: Mitsubishi AA104VJ02 LCD Panel

1. What is the AA104VJ02?A 10.4-inch industrial TFT LCD panel with 640x480 VGA resolution, CCFL backlight, and an LVDS interface, originally by Mitsubishi.

2. Is this panel still being manufactured?No, it is discontinued but widely available through aftermarket and specialist electronic component distributors.

3. Why is the resolution only VGA (640x480)?For perfect compatibility with legacy industrial, medical, and test equipment designed for that native signal output.

4. What does "CCFL backlight" mean?It uses Cold Cathode Fluorescent Lamps for illumination, requiring a high-voltage inverter, unlike modern LED-backlit panels.

5. Can I replace the CCFL with an LED backlight?Yes, it is technically possible via a modification kit, but it requires careful disassembly and is not risk-free.

6. What is the main use for this panel today?Primarily as a replacement/spare part for maintaining and repairing older HMI, medical, and test equipment.

7. What kind of interface does it use?A 20-pin single-channel LVDS (Low-Voltage Differential Signaling) interface.

8. Do I need a special controller to use it?Yes, you need an LVDS controller board that matches its specific pinout, voltage, and signal timing.

9. Are there direct modern equivalents?Modern 10.4-inch panels exist with LED backlights and higher resolutions, but they may not be pin-to-pin compatible without system redesign.

10. What should I check when buying one?Verify for dead/stuck pixels, CCFL backlight brightness and uniformity, and ensure the seller provides a compatibility datasheet.

Conclusion

The Mitsubishi AA104VJ02 is far more than a collection of outdated specifications. It is a specialized component engineered for endurance and compatibility within critical systems where failure is not an option. Its value proposition lies not in cutting-edge pixel density, but in its ability to seamlessly extend the operational life of expensive capital equipment long after its original production has ceased. This analysis underscores a fundamental principle in industrial design: technological progress is not always linear in application. The "right" component is the one that matches the system's lifecycle, environmental demands, and economic realities. For engineers and technical buyers navigating the complex landscape of display solutions, understanding the nuanced role of panels like the AA104VJ02—their architecture, integration hurdles, and enduring niche—is essential for making informed decisions that balance innovation with pragmatic support for the technological foundations of industry.